The float valve is fixed at the desired height on the container wall and is connected to the supply line. As the level rises, the float rises and passes through...

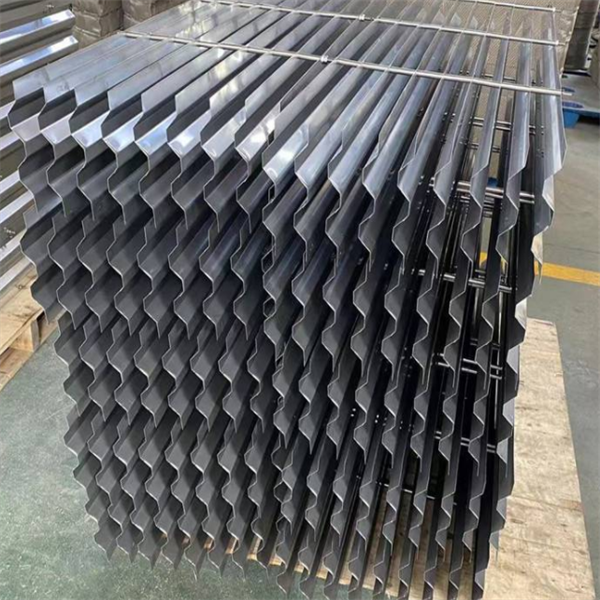

tray

Float valve - type: There are many types of float valve, there are circular float, and strip valve. Circular valves are mainly used in China. Among them, F1 type is commonly used, and there is a domestic ministry standard (JB1118). The standard valve body material can be carbon steel, stainless steel or acid resistant steel; Light valve thickness is 1.5mm, weight about 25g, heavy valve thickness is 2mm, weight about 33g.

The float valve is fixed at the desired height on the container wall and is connected to the supply line. As the level rises, the float rises and passes through the rod arm to close the valve. When the liquid level drops, the supply line opens and the medium flows in until the respective liquid level is reached again.

Application: industrial water treatment, chemical processing industry

In some practical applications, strip valves are better than F1 valves for the following reasons:

1. Strip type float valve has been used, the same kind of guide float valve, etc

2. High separation efficiency

3. Advantages for users: compared with the traditional float valve, it is not easy to fall off and not easy to jam

4. The processing capacity is more than 20% higher than F1 type float valve

5. The leakage, pressure drop and efficiency of the tray are similar to F1 float valve

Model | DN80 | DN100 | DN150 |

Noninal Diameter | 80 | 100 | 150 |

outside Diameter and thinkness of cap | 80×2 | 100×3 | 158×3 |

outside Diameter and thinkness of riser | 57×3.5 | 70×4 | 108×4 |

Total Height | 95 | 105 | 107 |

Height of Cap | 65 | 75 | 73 |

Height of Riser | 57 | 62 | 64 |