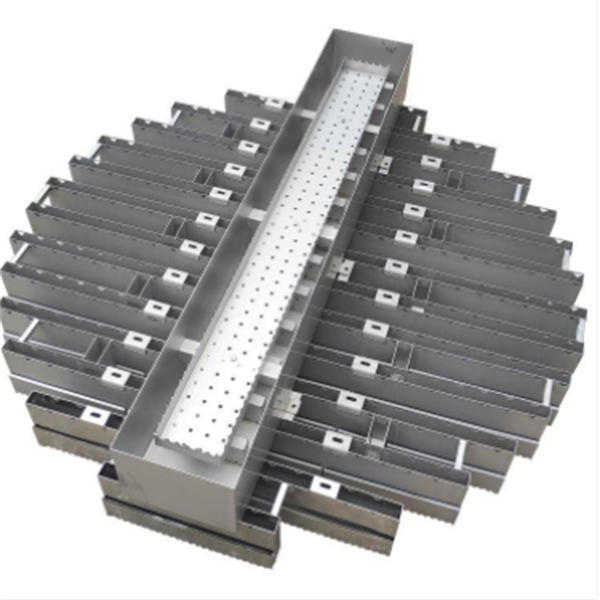

Main types of metal bubble cover tray: stainless steel bubble cover tray main types; Round bubble cover tray, strip bubble cover tray, tunnel tray, S - shaped tray force.

tray

Inside the tower of ammonia project, metal bubble cover tray air stripping tower F1 floating valve tray, including round bubble cover tray, strip bubble cover tray, all kinds of special-shaped special bubble cover, is one of the earliest trays used in industry. Is in the tray plate open many round holes, each round hole welded on a short tube, called the pipe, and then cover a "hat", called the bubble cover, bubble cover around a lot of strip holes. When working, the liquid from the upper tray through the liquid pipe into the lower tray, and then cross the tray tray, flow into the next layer of tray; The gas rises from the lower tray into the lifting pipe, and then escapes to the liquid layer between the bubbles through the annular passage and the strip holes of the bubbles.

Advantages:

1, because the float valve can be free to rise and fall, close or open according to the size of the gas speed, when the gas speed changes, the size of the opening can be adjusted automatically, so its operation "elastic" (generally 5~9), suitable for production fluctuation and change;

2. The production capacity of the floating valve tower is larger, which is about 20%~40% higher than that of the bubble cover tower; Similar to sieve plate tower;

3, the valve tower gas liquid two phase contact is sufficient, therefore, the tray efficiency is high, generally 15% higher than the bubble cover tower;

4. When the gas in the floating valve tower rises along the periphery of the valve plate, it only shrinks, turns and expands once. Therefore, the tray pressure drop of the floating valve tower is smaller than that of the bubble cover tower.

5, because the floating valve tower constantly moving up and down, the valve hole is not easy to be blocked by dirt or sticky materials, cleaning plate is also relatively easy;

6. Compared with bubble cover tower, the floating valve tower has simple structure, easy manufacturing and convenient maintenance. Therefore, the manufacturing cost is 60%~80% lower than that of bubble cover tower.