Polypropylene plastic grid filler is mainly plastic profile - plate as the main mass transfer component. The plastic sheet is perpendicular to the tower section...

tray

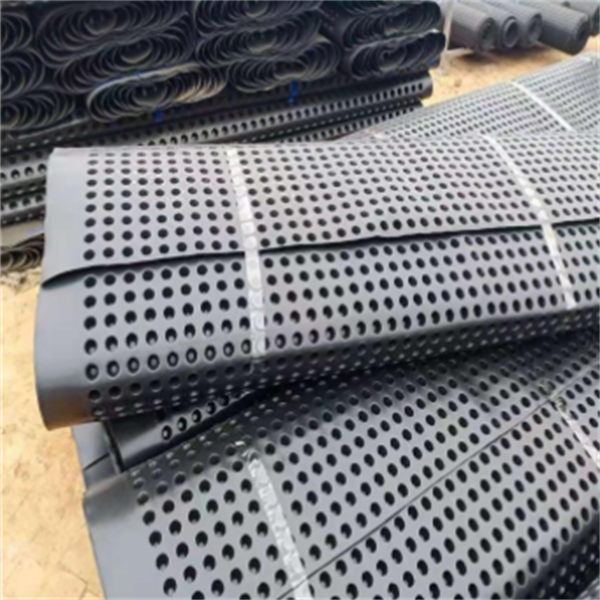

Polypropylene plastic grid filler is mainly plastic profile - plate as the main mass transfer component. The plastic sheet is perpendicular to the tower section and parallel to the direction of air flow and liquid flow. The upper and lower layers rotate at 45°. During operation the grid filler is able to provide the specific surface area so that gas rise and liquid fall resistance are reduced. Liquid by gravity along the surface of the grid down, and rising gas contact, on the surface of the plastic sheet is a film flow down, gas as a border phase flow from bottom to bottom, and liquid film contact mass transfer, gas liquid form droplets or film contact, so the mass transfer effect is good, high absorption efficiency. Under the scour of steam flow and water flow in the desulfurization tower, the gas and liquid have a fixed channel, and the fluid is constantly scoured and contacted between the plates, so that the gas and liquid containing solid particles or dust will not stagnate, deposit, siltation and blockage on the surface of the filler. Therefore, the grid packing is a new structured packing with large flux, low pressure drop and no blocking tower. It has great advantages for gas cooling, dust removal and desulfurization.

model | Plate spacing mm(positioning distance) | Accumulation is severekg/m³ | Specific surface aream²/m³ | Void fraction% | thicknessmm |

Plastic grilleGS-4 | 12-50 | 150 | 64.6 | 87.15 | 4-6 |

The metal grilleGSL-1 | 50 | 76 | 79.05 | 98.95 | 0.5 |

The metal grilleGSL-2 | 30 | 90 | 98.5 | 98.95 | 0.5 |