PVC/PP plastic baffle demister PP baffle demister principle in industrial production process and industrial emissions in the process, the gas and liquid separat...

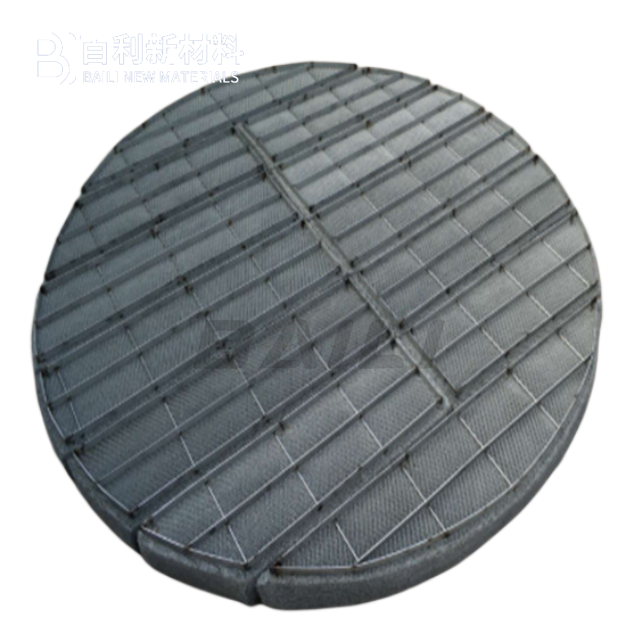

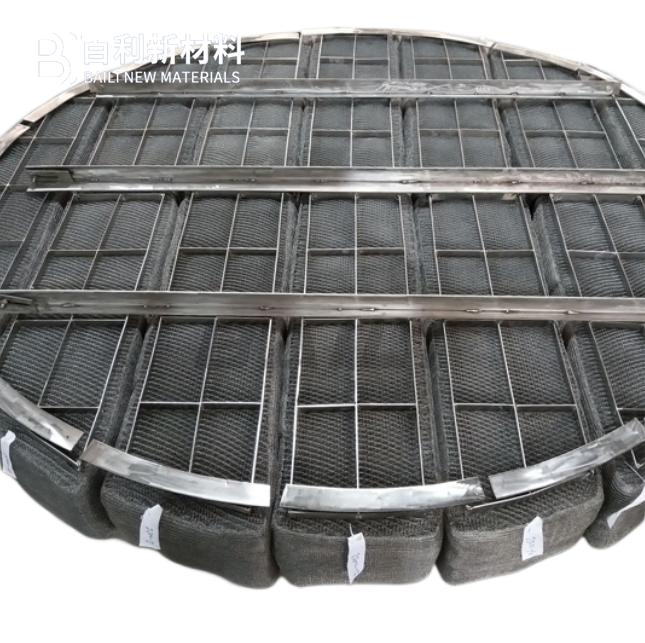

mist eliminator

PVC/PP plastic baffle demister PP baffle demister principle in industrial production process and industrial emissions in the process, the gas and liquid separation, is an important process in the operation of a lot of product process will be entrained in the gas phase entrainment or dust in the separation, to make the production smoothly. And the foam or dust particle diameter is very small, such as mechanical foam particle diameter between 1.0~150um, and condensed foam particle diameter between 0.10~30um, separation of these foam or dust, both to high separation efficiency, small resistance, not easy to block, but also the installation of small area, economic operation, reliable, convenient operation.

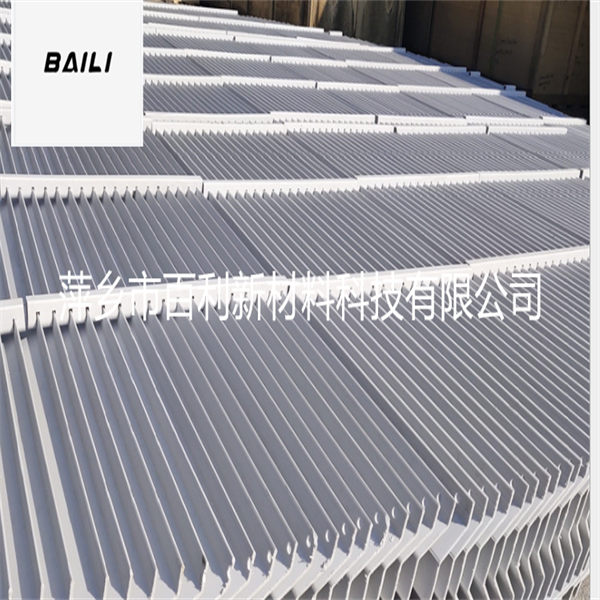

1) Defogging efficiency: under normal operating conditions, the droplet concentration in the outlet flue gas of the defogger is less than 75mg/Nm3;

(2) Pressure drop: the interference before and after the mist eliminator is not considered to ensure that the pressure of the whole mist eliminator system is reduced to 120Pa under the smoke load.

(3) High temperature resistance: 80--95℃.

(4) Pressure resistance: ensure that the blade can work normally when the washing pressure is 0.3mpa.

(5) Washing nozzle: full conical nozzle, flushing water injection Angle is 90-120 degrees, spray solid cone, can ensure that the blade is completely covered. (The water consumption is designed for large gas load. Considering the requirements of water balance in the system, if the gas load decreases, the water consumption can be reduced by half by increasing the washing interval time). A Mist catcher, the working principle of mist eliminator; The flue gas passes through the bent channel of the demister, separating the droplets entrained in the airflow under the action of inertia force and gravity: After desulfurization of flue gas velocity through the mist eliminator, flue gas was rapid, continuous change direction, because of the action of centrifugal force and inertia, flue gas inside the droplets hit the mist eliminator blades was set down, droplets together to form water, because of the action of gravity, down to the slurry pool, implements the gas-liquid separation, make through the mist eliminator out the back of flue gas in meeting the requirements of the mist.

The products can be produced according to customer requirements. And provide design, manufacturing and installation of one-stop services.

Welcome new and old customers to call, letter or visit me to negotiate business, guidance work.