The tube distributor/liquid distributor is a key component in the packed column, which not only affects the mass transfer efficiency of the packing, but also affects the operational elasticity of the ...

distributor

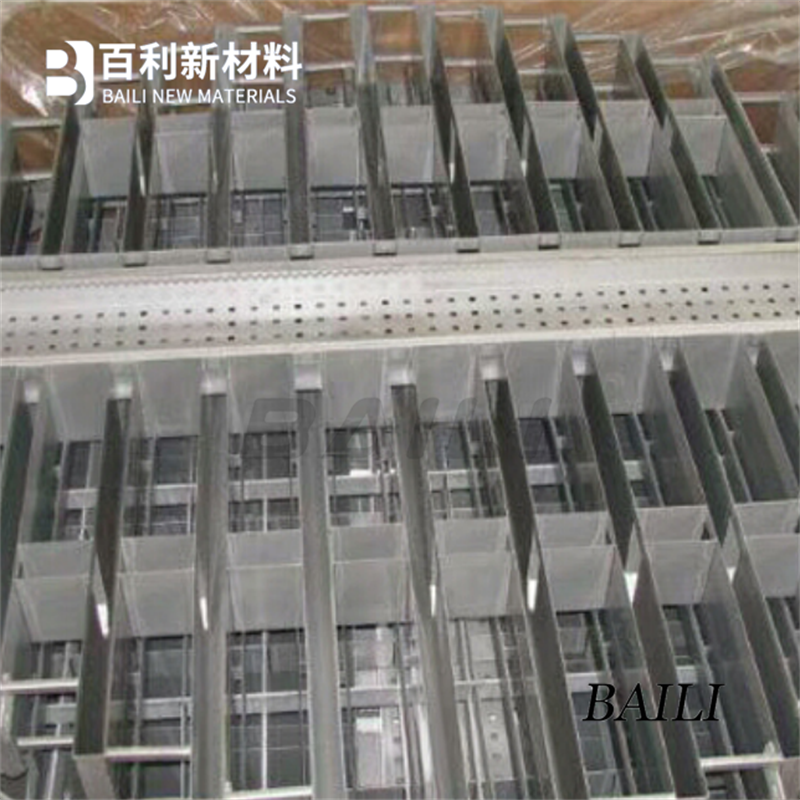

The tube distributor/liquid distributor is a key component in the packed column, which not only affects the mass transfer efficiency of the packing, but also affects the operational elasticity of the packing.

In order to reduce the amplification effect caused by poor liquid distribution and give full play to the efficiency of packing, a liquid distributor must be installed in the packing tower to distribute the liquid evenly on the top of the packing layer. The quality of the initial distribution of liquid not only affects the mass transfer efficiency of the packing, but also affects the operating elasticity of the packing. Therefore, the liquid distributor is a very key component in the packed tower. There are many kinds of distributors. The selection is based on distribution quality, operating elasticity, handling capacity, gas resistance, levelness and many other aspects

Plastic tube distributor/disc liquid distributor features:

1. Excellent liquid distribution performance, suitable for more spray points and lower liquid load occasions

2. No solid particles are required in the material, and a filter screen should be set at the inlet of the vertical pipe

3. The tube type liquid distributor has good flexibility in operation

4. In the case of high flexibility of operation, double row tube type liquid distributor can be used

5. Suitable for large, medium and small towers

The material of tube distributor/liquid distributor is: 304 tube distributor/liquid distributor, 316 tube distributor/liquid distributor, 316L and other stainless steel tube distributor/liquid distributor

Liquid distributor classification:

1, according to the distribution of fluid power: gravity type liquid distributor (pass, weir, pressure type liquid distributor, spray type, porous tube type)

2, according to the shape of the distributor: tube, double layer row, trough, plate, impact, nozzle, pagoda, lotus, combined type, etc.

3, according to the form of liquid leaving distributor: flow type, overflow type.

4, according to the number of liquid distribution: single stage, multistage.

5. According to the combination of distributor, it can be divided into tube groove type, hole groove type and slot plate type

The product of the company can be produced according to customer requirements!

The company produces and sells all kinds of packing, covering all the needs of packing.

Specification material can be specially customized

Welcome to consult!