Honeycomb ceramic heat accumulator is the key and core component of regenerative high temperature combustion (HTAC) technology. Regenerative high temperature co...

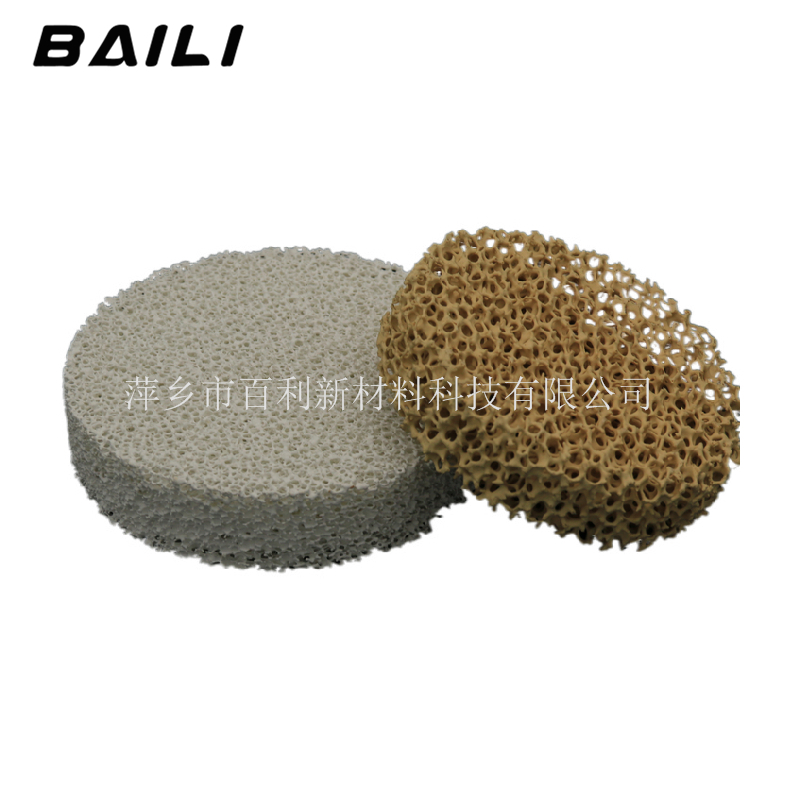

Honeycomb ceramics

Honeycomb ceramic heat accumulator is the key and core component of regenerative high temperature combustion (HTAC) technology. Regenerative high temperature combustion technology (HTAC technology) is a new concept of combustion technology, it is the recovery of flue gas waste heat and combustion and reduce NOx emissions and other technologies inorganic combination, so as to achieve the dual purpose of energy saving and reduce energy saving NOx emissions. Honeycomb ceramic heat accumulator has been widely used in all kinds of push-steel heating furnace, stepping heating furnace, heat treatment furnace, forging furnace, melting furnace, ladle/tundish oven, soaking furnace, radiant tube burner, hood furnace, blast furnace hot blast furnace; All kinds of ceramic kilns and glass kilns in building materials industry; All kinds of tubular heating furnaces, cracking furnaces and other industrial furnaces in petrochemical industry.

SiO2 | Al2O3 | MgO | Fe2O3 | Na2O | K2O |

48-51% | 31-34% | 14-16% | <0.5% | 0.5% | 0.5% |

Index | Value | ||||

Cordierite gross density (g/cm3) | 1.9-2.0 | ||||

Average Linear Expansion(20-1000℃)(10-6/k-1) | <2 | ||||

Specific heat capacity (KJ/Kg) | 830-900 | ||||

Temperature cycle resistance(K) | 300 | ||||

Max operation Temp.(℃) | 1300 | ||||

Thermal shock resistance(℃) | 800 | ||||

Acid resistance(%) | >99 | ||||

Alkali resistance(%) | >85 | ||||

Water absorption(Wt%) | 22±5 | ||||

Spec. (mm) | Quantity of Channels | Wall Thickness (mm) | Surface Area (m2/m3) | Free Volume (%) | Average Weight (min.)(kg/m3) |

150*150*300 | 60*60 | 0.5 | 1315 | 70 | 680 |

150*150*300 | 50*50 | 0.7 | 1050 | 58 | 680 |

150*150*300 | 40*40 | 0.7 | 883 | 65 | 518 |

150*150*300 | 25*25 | 1 | 573 | 67 | 502 |