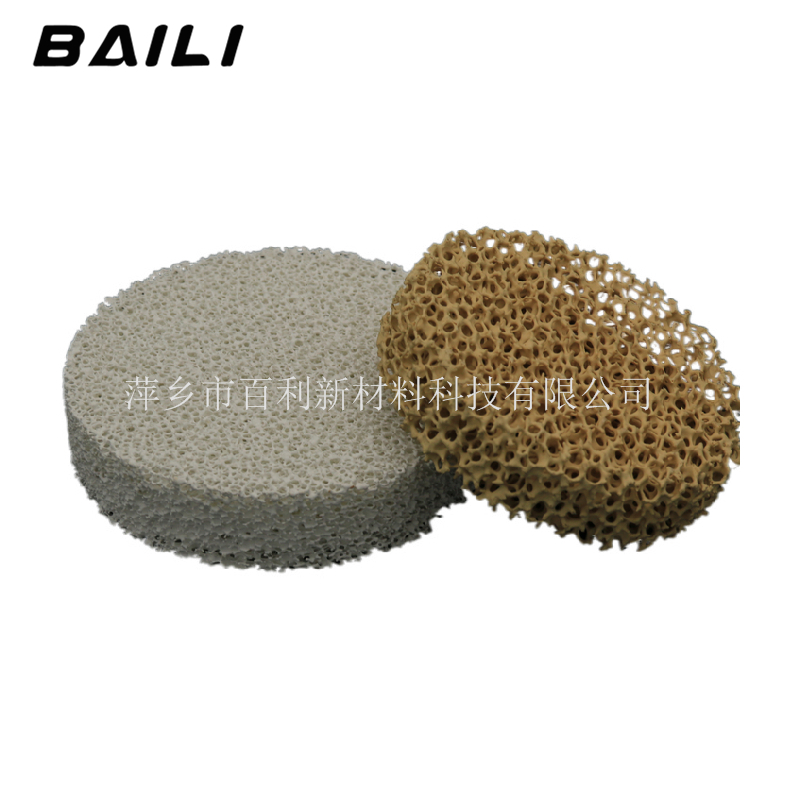

Foam ceramic filters can significantly improve the quality of cast iron parts and reduce the rejection rate. They can also be used in continuous casting and rol...

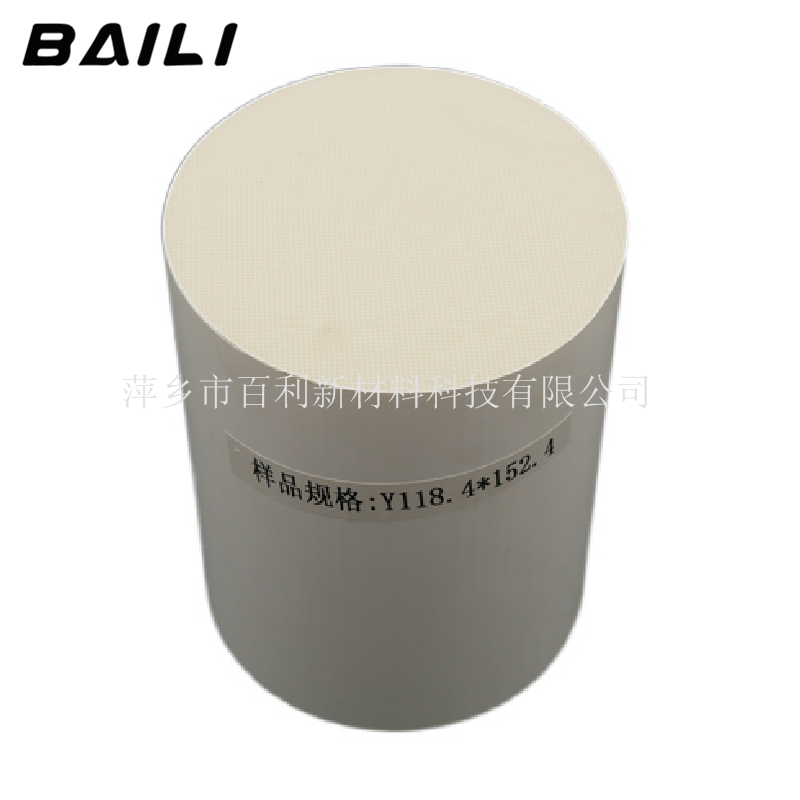

Honeycomb ceramics

Foam ceramic filters can significantly improve the quality of cast iron parts and reduce the rejection rate. They can also be used in continuous casting and rolling processes. They can be manufactured in different sizes and thicknesses according to the runner and casting weight. Foam ceramic filter has an excellent filtering effect on copper water or molten iron. Using three-dimensional structure, it can effectively remove oxidized inclusions and other non-metallic inclusions by blocking capture and adsorption. Whether gray iron, ductile iron or shaft body, cylinder body or complex large, precision hardware parts after filtration, product quality will be stable and satisfactory results.

Filter size (mm) | Ductile iron (≥kg) | Grey cast iron (copper alloy) (≥kg) |

40×40×11 | 15 | 30 |

50×50×22 | 30 | 60 |

75×50×22 | 75 | 150 |

100×50×22 | 110 | 220 |

75×75×22 | 110 | 240 |

100×100×22 | 20 | 390 |

150×150×25 | 400 | 780 |

200x150x25 | 500 | 1000 |