Plastic porous combination of serial, plastic PP diamond ring structured packing to overcome the light ceramic packing, all porcelain packing, wood grid packing...

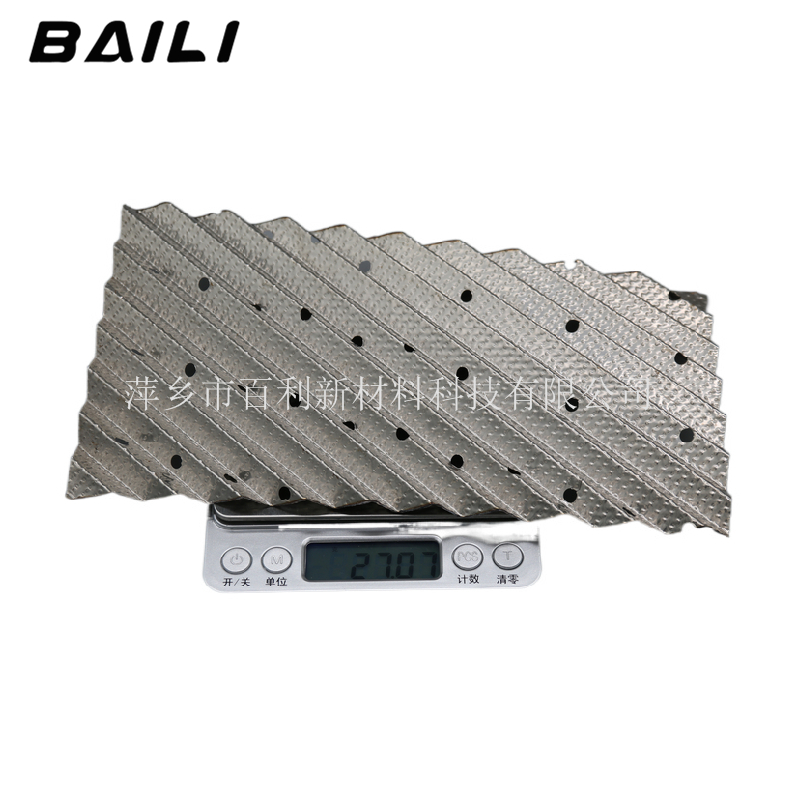

Metal structured packing

Plastic porous combination of serial, plastic PP diamond ring structured packing to overcome the light ceramic packing, all porcelain packing, wood grid packing corrosion, bulk packing installation trouble, all porcelain packing surface smooth dust removal effect low drawbacks. The opening rate of plastic prismatic porous composite ring structured packing is more than 40%, and the filling weight is only 50% of the original bulk packing. In order to meet the gas phase liquid is uniformly distributed in the bottom of the AD hoc six feet, achieved the packing single gas-liquid redistribution and improves the gas-liquid mixing frequency, outside looks like a grating for packing support, but its individual small, single alone, 245 mm in diameter, height 100 mm, each edge Angle to highlight a little, little weight from foot to foot 15 mm high, In the sealed tower, the contact and circulation of specific surface area are increased when the products overlap, so the design is supported by small feet, and the operation is more ideal.

size | Accumulation number(个/m3) | Packing density(Kg/m3) | Void fraction(%) | Specific surface area(m2/m3) | Dry packing factor( m-1) |

245*100mm | 150 | 65 | 0.93 | 86 | 110 |