Polytetrafluoroethylene (PTFE for short), commonly known as "non-stick coating" or "easy to clean material". This material has the characteristics of acid and a...

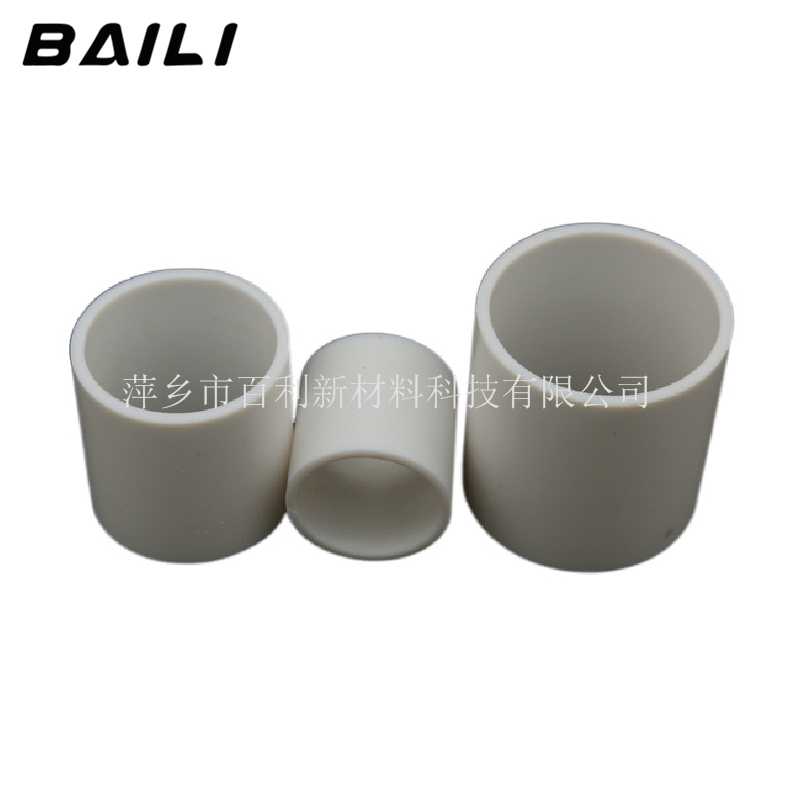

Plastic bulk packing

Polytetrafluoroethylene (PTFE for short), commonly known as "non-stick coating" or "easy to clean material". This material has the characteristics of acid and alkali resistance, resistance to all kinds of inorganic solvents, almost insoluble in all solvents. In the meantime, polytetrafluorthylene has the characteristic that can bear or endure high temperature, its friction coefficient is extremely low, can make lubricate action so, also became the ideal coating inside easy clean conduit. It has solved many problems in chemical, petroleum, pharmaceutical and other fields. Ptfe seals, gaskets, gaskets. Polytetrafluoroethylene seals, gaskets, sealing gaskets are made of suspended polytetrafluoroethylene resin moulding. Compared with other plastics, ptfe is resistant to chemical corrosion and has been widely used as a sealing and filling material.

Polytetrafluoroethylene in 200C above, the beginning of very trace cracking, even if the temperature rises to the crystal melting point 327C, still cracking is very few, weight loss per hour for two ten thousand. But when heated to more than 400C, the pyrolysis speed gradually accelerates, producing toxic gas. Therefore, the sintering temperature of PTFE is generally controlled at 375~380C. The van der Waals attraction between ptfe molecules is small, easy to produce inter-bond sliding, so PTFE has a very low coefficient of friction and non-viscosity, friction coefficient is low in the known solid materials. The thermal conductivity of PTFE is low, which has great influence on its molding process and application. Its not only poor thermal conductivity, and linear expansion coefficient is large, adding filler can be appropriate expansion coefficient. Creep phenomenon, also known as "cold flow", occurs under load and can be reduced by adding filler.