In order to reduce the amplification effect caused by the poor distribution of liquid and give full play to the efficiency of packing, a distributor should be i...

distributor

Functions of the distributor:

Distributor is the liquid on the top of the filler or a certain height for uniform initial distribution or redistribution. To improve the effective surface of mass and heat transfer, improve the phase contact, thus improving the efficiency of the tower. The experimental results show that the liquid flow in the packing layer is not uniform plug flow, but exists groove flow, deflection flow and wall flow. This will cause the amplification effect and end effect of the packed column. The rational design and selection of liquid initial distributor and redistribution distributor is to reduce and prevent the amplification effect of the packed column, so as to reduce the height and diameter of the column. To reduce the cost of construction or operation.

Distribution features:

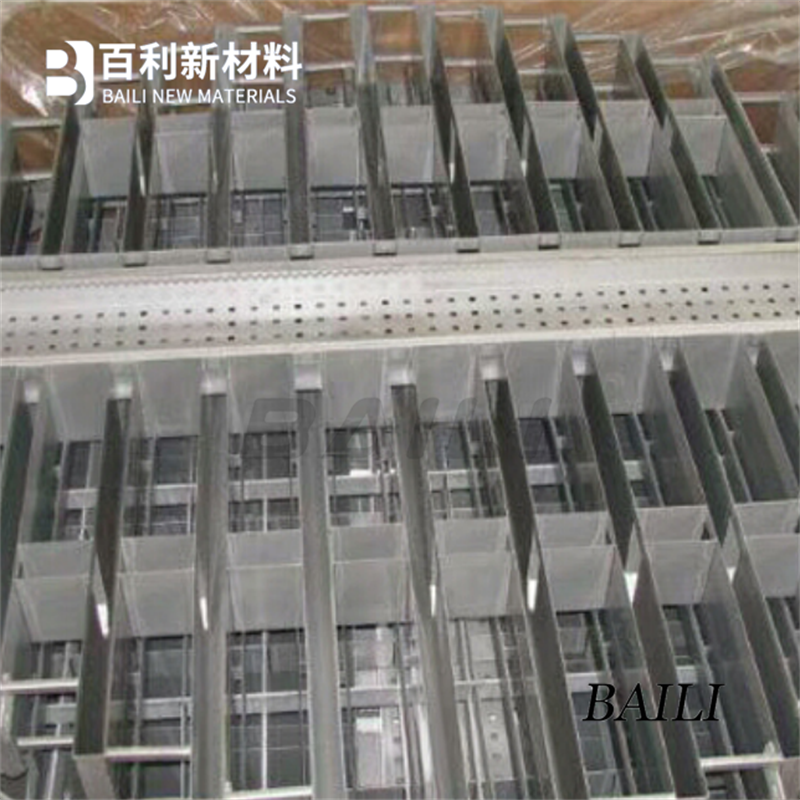

Trough plate type liquid distributor is actually the overflow disc or mesh disc retrofit of liquid distributor, its main features are: multi-function, low placeholder, anti-clogging, prevent entrainment, high elasticity, liquid level, appropriate extraction, flash, liquid and gas are, the valley of heat transfer and resistance to swing, good mixing, level constant, prevent leakage, resistance to deformation, net canal chang, lower reaction pressure, the application

Distributor type:

There are many types of liquid distributor with different structures, which can be divided into several categories according to different types:

According to the use can be divided into: general type and special general type. The former refers to the conventional operating elasticity, spray density, gas velocity range, and is suitable for general fluids; The latter includes high elasticity, super or super small spray density, high gas velocity, special materials and other occasions.

According to the driving force of liquid flow: pressure type and gravity type.

According to the liquid outflow mode, there are mainly hole flow and weir flow, as well as capillary flow, film flow on the diversion plate and so on.

Divide by structure shape: common have tube type, trough type, disc type and combinative type.

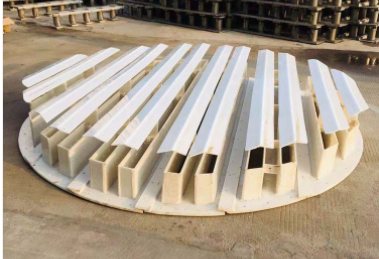

PTFE liquid distributor material characteristics:

PTFE is reputed as the "king of plastics", Chinese trade name "teflon", "teflon", "Teflon" and so on. It is made of tetrafluoroethylene polymerized polymer compound, has excellent chemical stability, is one of the performance materials in the world today, in addition to molten and liquid fluorine, can withstand all other chemicals, used in all kinds of acid and alkali resistance and organic solvents, Sealing, high lubrication non-stickiness, electrical insulation and good aging resistance, temperature resistance (can work in +250℃ to -180℃ temperature for a long time).

Tetrafluoroethylene distributor PTFE liquid distributor various specifications manufacturers can be customized production