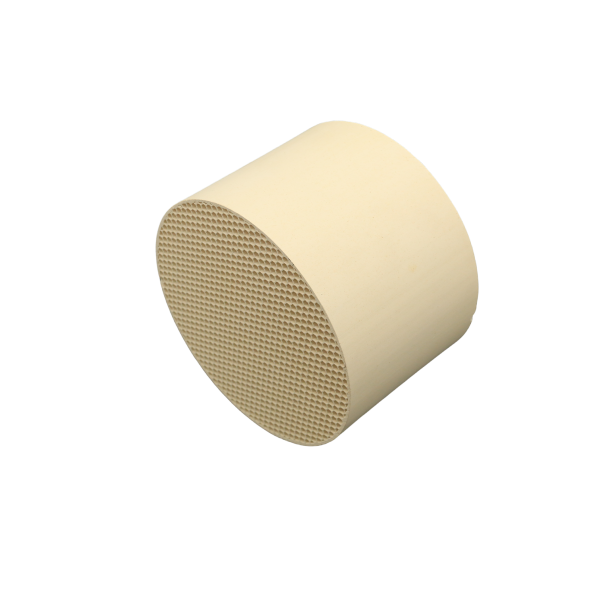

Honeycomb ceramics, as a kind of high-efficiency filtration material, plays an important role in industrial furnaces due to its unique pore structure and excellent physicochemical properties.

Especially in the context of energy saving and environmental protection requirements, the value of honeycomb ceramics in the application of industrial furnaces has become more and more prominent.

First of all, honeycomb ceramics in the industrial furnace plays a key role in filtration. Industrial furnace in the production process, often produces a large amount of exhaust gas and smoke,

not only pollution of the environment, but also affect the normal operation of the equipment. Honeycomb ceramics, as a kind of high-efficiency filtration material, can effectively trap and remove

harmful substances in the exhaust gas, such as particles, sulfur dioxide, nitrogen oxides and so on. This not only reduces the pollution to the environment, but also extends the service life of

the industrial furnace.

Secondly, honeycomb ceramics have good energy-saving effect in industrial furnace. Honeycomb ceramics have excellent thermal conductivity, which can effectively reduce the temperature

gradient in the industrial furnace and reduce heat loss. At the same time, the hole structure of honeycomb ceramics provides a larger contact area, which enables the heat to be transferred

more evenly and improves the efficiency of energy use. Therefore, industrial furnaces using honeycomb ceramics can ensure productivity while reducing energy consumption and saving

costs for enterprises.

In addition, honeycomb ceramics also has excellent high temperature resistance, corrosion resistance and other properties, can be in the harsh environment of long-term stable operation.

This greatly reduces the maintenance and replacement costs of industrial furnaces, for enterprises to bring real economic benefits.

However, despite the significant advantages of the application of honeycomb ceramics in industrial furnaces, there are still some challenges. For example,

how to further improve the filtration efficiency and life of honeycomb ceramics, how to reduce production costs and so on. In the future,

with the continuous progress of scientific research and technology and industrial upgrading, I believe that these challenges will be effectively solved.

In general, the application of honeycomb ceramics in industrial furnaces and energy saving effect is remarkable, has a broad development prospect.

With the improvement of environmental protection requirements and the implementation of energy saving and emission reduction policies, the application of cellular ceramics in

the field of industrial furnace will be more widely used, to promote green manufacturing and sustainable development to make greater contributions.