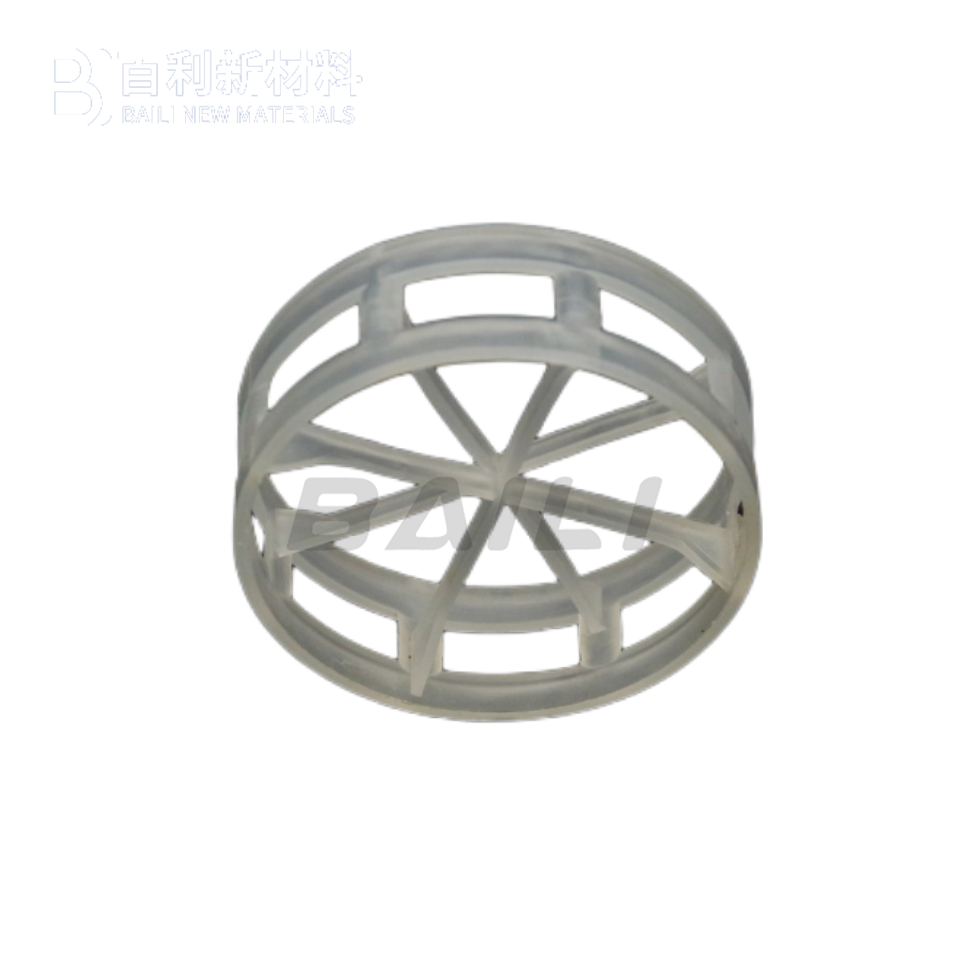

The high diameter ratio of plastic flat ring packing is 0.2-0.4, the plastic flat ring packing cancelling the flanging of step ring, using the inner curved arc ...

Plastic bulk packing

The high diameter ratio of plastic flat ring packing is 0.2-0.4, the plastic flat ring packing cancelling the flanging of step ring, using the inner curved arc reinforcement to improve the strength of plastic flat ring packing, can be orderly arranged in the heap, the flow channel structure is reasonable, the plastic flat ring packing in the processing capacity and mass transfer performance are improved. Fluid resistance is small (pressure drop is small), flow is large, fluid through the plastic flat ring packing layer gas-liquid contact is good, groove flow and wall flow trend is small, excellent mass transfer performance.

Plastic PP flat ring filler is mainly used

The plastic flat ring filler is mainly used for dimethyl sulfoxide heavy aromatic reverse pumping, furfural refining of lubricating oil, LPG removing H2S, lignol, phenol containing wastewater treatment, and NHD desulfurization tower removing hydrogen sulfide in the conversion gas

Plastic Flat Super Mini Ring | ||||||

specifications | D×H×T mm | Accumulation number n/m³ | Specific surface area m²/m³ | Void fraction % | Dry packing factor m-1 | note |

Φ25 | 25×9×0.5 | 160000 | 228 | 0.936 | 280 | |

Φ38 | 38×12.7×0.7 | 48000 | 150 | 0.95 | 175 | |

Φ50 | 50×17×0.8 | 21500 | 115 | 0.965 | 156 | |

Φ75 | 75×22.5×1.0 | 5800 | 88 | 0.975 | 90.2 | |